At PCM Products, we have total control of your parts from start to finish because all the processes are done in our 50,000 square foot facility. This enables us to work with your project from prototype to short runs or high volume production. Having the in-house capabilities allows for better lead times, very competitive part pricing and most importantly quality control.

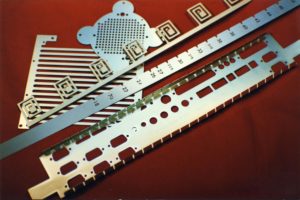

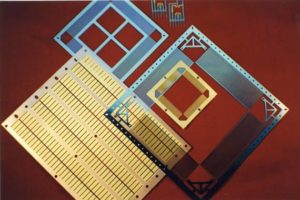

PCM Products offers metal etching and finishing for precision components of multiple thicknesses for parts up to 58” wide. We can chemical mill and etch holes of any shape for products ranging from intricate decorative products to aluminum skins for honeycomb panels used in aircraft, satellites, ships and aerospace applications.

Our cost-effective etching uses inexpensive CAD design photos as stencils that allow us to quickly perform any design modifications. With specialized masking skills, PCM Products accommodates finishing requirements for products that require selective plating. In addition, our finishing options include chemical engraving, heat treating and black oxide coatings on steel and copper.