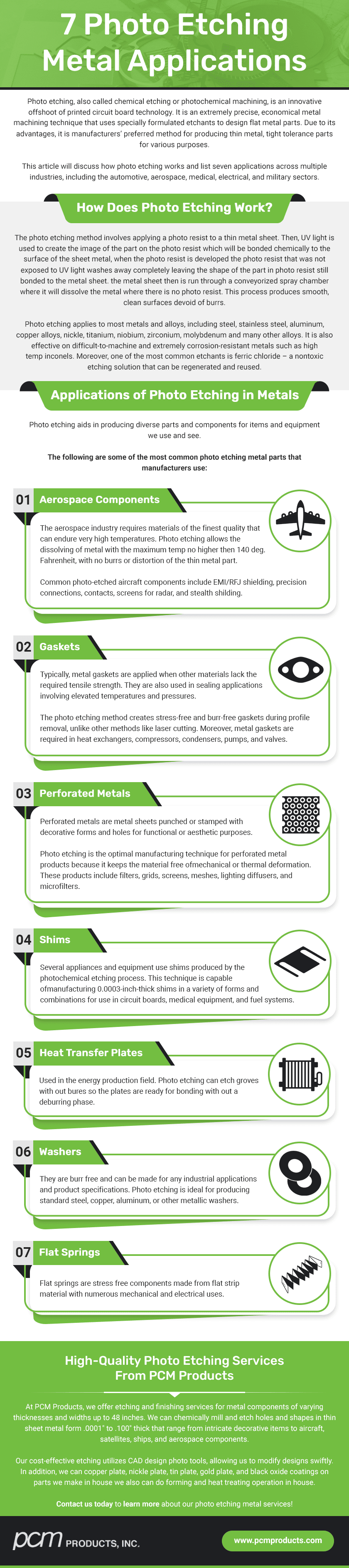

Photo etching, also called chemical etching or photochemical machining, is an innovative offshoot of printed circuit board technology. It is an extremely precise, economical metal machining technique that uses specially formulated etchants to design flat metal parts. Due to its advantages, it is manufacturers’ preferred method for producing thin metal, tight tolerance parts for various purposes.

This article will discuss how photo etching works and list seven applications across multiple industries, including the automotive, aerospace, medical, electrical, and military sectors.

How Does Photo Etching Work?

The photo etching method involves applying a photo resist to a thin metal sheet. Then, UV light is used to create the image of the part on the photo resist which will be bonded chemically to the surface of the sheet metal, when the photo resist is developed the photo resist that was not exposed to UV light washes away completely leaving the shape of the part in photo resist still bonded to the metal sheet. the metal sheet then is run through a conveyorized spray chamber where it will dissolve the metal where there is no photo resist. This process produces smooth, clean surfaces devoid of burrs.

Photo etching applies to most metals and alloys, including steel, stainless steel, aluminum, copper alloys, nickle, titanium, niobium, zirconium, molybdenum and many other alloys. It is also effective on difficult-to-machine and extremely corrosion-resistant metals such as high

temp inconels. Moreover, one of the most common etchants is ferric chloride – a nontoxic etching solution that can be regenerated and reused.

Applications of Photo Etching in Metals

Photo etching aids in producing diverse parts and components for items and equipment we use and see. The following are some of the most common photo etching metal parts that manufacturers use:

Aerospace Components

The aerospace industry requires materials of the finest quality that can endure very high temperatures. Photo etching allows the dissolving of metal with the maximum temp no higher then 140 deg.

Fahrenheit, with no burrs or distortion of the thin metal part.

Common photo-etched aircraft components include EMI/RFJ shielding, precision connections, contacts, screens for radar, and stealth shilding.

Gaskets

Typically, metal gaskets are applied when other materials lack the required tensile strength. They are also used in sealing applications involving elevated temperatures and pressures.

The photo etching method creates stress-free and burr-free gaskets during profile removal, unlike other methods like laser cutting. Moreover, metal gaskets are required in heat exchangers, compressors, condensers, pumps, and valves.

Perforated Metals

Perforated metals are metal sheets punched or stamped with decorative forms and holes for functional or aesthetic purposes.

Photo etching is the optimal manufacturing technique for perforated metal products because it keeps the material free ofmechanical or thermal deformation. These products include filters, grids, screens, meshes, lighting diffusers, and microfilters.

Shims

Several appliances and equipment use shims produced by the photochemical etching process. This technique is capable ofmanufacturing 0.0003-inch-thick shims in a variety of forms and combinations for use in circuit boards, medical equipment, and fuel systems.

Heat Transfer Plates

Used in the energy production field. Photo etching can etch groves with out bures so the plates are ready for bonding with out a deburring phase.

Washers

They are burr free and can be made for any industrial applications and product specifications. Photo etching is ideal for producing standard steel, copper, aluminum, or other metallic washers.

Flat Springs

Flat springs are stress free components made from flat strip material with numerous mechanical and electrical uses.

High-Quality Photo Etching Services From PCM Products

At PCM Products, we offer etching and finishing services for metal components of varying thicknesses and widths up to 48 inches. We can chemically mill and etch holes and shapes in thin sheet metal form .0001″ to .100″ thick that range from intricate decorative items to aircraft, satellites, ships, and aerospace components.

Our cost-effective etching utilizes CAD design photo tools, allowing us to modify designs swiftly.

In addition, we can copper plate, nickle plate, tin plate, gold plate, and black oxide coatings on parts we make in house we also can do forming and heat treating operation in house.

Contact us today to learn more about our photo etching metal services!